Steel Tubing

Pressures of 200 to 240 atmospheres (2950-3500 psi) are dangerous. Caution and diligence are requisite to prevent accidents and injuries. The tubing that transmits the pressurized gas needs to safely withstand these pressures. Below is a brief discussion of some of the calculations used to verify that the tubing is safe.

One liquefies air, nitrogen or oxygen by compressing the gas and cooling it below a critical temperature. As the compressed gas leaves the compressor it is hot because work was done on the gas during adiabatic compression. The gas enters a pre-cooler. This is 20 feet of coiled 1/4OD cold-rolled 304 seamless stainless steel tubing. The tubing has a wall thickness of 0.035 inches. The tubing has aluminum fins to enhance the rate of heat exchange. This coil sits in an ice bath and cools the compressed gas. We should do a quick calculation to verify the pressure rating of the tubing since we deal with pressures of 3500 psi.

First, you should verify the strength of the tubing purchased for one's individual needs. The room temperature yield tensile strength of the tubing used for this project is 35,000 psi. This is the pressure at which the tube will permanently deform 0.2%. This is not the same as the ultimate tensile strength, which is the pressure that the material fails.

The formula relating pressure and wall tension is Laplace’s Formula T = PR/t, where T is tension (psi), P is pressure (psi), R is the effective radius and t is the wall thickness. Rearranging, we get P = Tt/R Using, T = 35,000 psi, t = 0.035 inches, R = 0.25/2 = 0.125 inches we get the maximum pressure 9800 psi. If we use a safety factor of 3 we have a working pressure of 3270 psi at room temperature. The yield strength increases as the temperature decreases. The low temperature (-320F) yield strength of 304 stainless steel is 56,000 psi. This gives a working pressure of 5230 psi if one uses a safety factor of three.

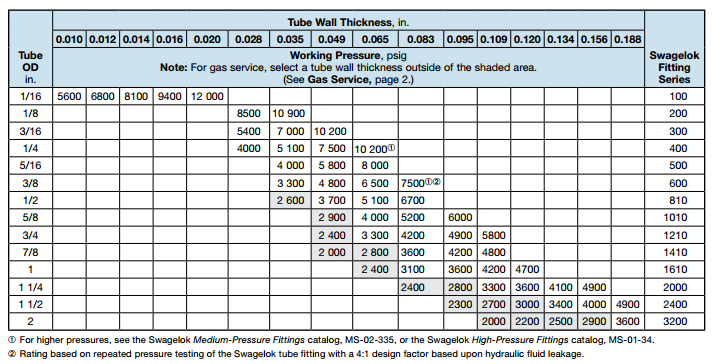

Below is a table with suggested working pressures for stainless steel tubing.

The tubing also comes in a wall thickness of 0.027 inches. The thinner wall would allow for a more efficient transfer of heat, enabling a more rapid cooling. A quick calculation shows that this tubing should withstand a pressure of 7000 psi, or 2330 psi with a 3x safety factor. I was hesitant to use this tubing because the wall is so thin I was afraid that a small sharp bend would be a setup for an integrity failure. Also, the working pressure I was using would be above the 3x safety factor. The 0.035 inch thickness seemed much safer, and safety is of paramount importance.