Overview of the system

While the operation is not hard to understand, getting it to work is a bit of a challenge. I will go over each part of the system and where one can obtain them. We will begin with a quick overview of the system.

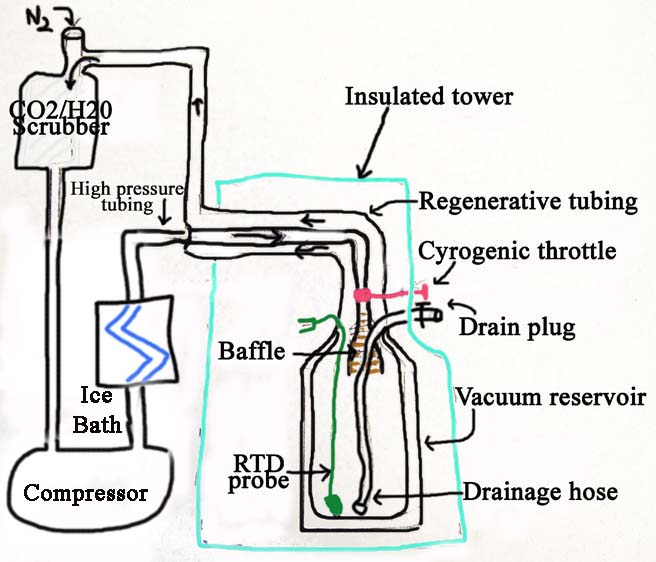

Below is the liquid nitrogen generator. Air or nitrogen gas goes into the intake where H20 and CO2 are removed. This is necessary because they will solidify and clog the throttle once they are below their freezing points (32F and -109F). A micron filteris used to remove particles from entering the compressor.

The compressor pressurizes the gas to 200 atmospheres. The high pressure tubing goes through an ice bath to lower the temperature of the compressed gas. The tubing then goes through a countercurrent, regenerative coil. Cold, low pressure exhaust gas further cools the high pressure gas on its journey to the throttle.

The cold compressed gas expands to a very cold low pressure gas. The baffle reduces the speed of the gas jet. When cold enough, droplets of liquified gas collect and fall to the bottom. High-grade insulation surrounds the entire regenerative system to minimize heat into the system.