Molecular Sieve Zeolite for CO2 H20 Scrubbing

Water freezes at 32F. Carbon dioxide freezes at -109F. If either of these substances are in the cooling tower they will solidify and clog the throttle in a very short time. Therefore, one must remove them from the fresh gas stream.

One achieves this will a scrubbing system. Back in the late 1800's Linde used potash (KOH, potassium hydroxide) to remove the water. Today we can use safer, more eligant materials like molecular sieve.

Molecular sieve desiccants are extremely effective at removing water from liquids and gases. They are even more effective silica gel or activated alumina , because of their crystalline composition; they can create virtually water-free products. These sieves are very useful in cryogenic operations where liquefaction of gases is required and water must be eliminated to avoid freezing.

Molecular sieves offer a variety of adsorption selectivity based on molecular size, molecular affinity for the sieve crystal surface, and shape of the molecule. Using this typeof system is exceptionally uncomplicated for diminishing impurities to practically indiscernible levels compared to other liquid separation systems. The ease of use and superior efficiency when compared to other adsorption systems makes the most popular engineering solution a molecular sieve system. Furthermore, molecular sieves can be regenerated by heating it to an optimal temp from 130°C to 250°C.

I used 20lbs of 13X molecular sieve for my flow of 3 scfm. 13X Molecular Sieve has a pore size of roughly 10A. This is considerably larger than any of the A type openings. This desiccant is used primarily for refinements of liquid and gases because it offers synchronized absorption for bi-molecule and tri-molecule. It can co-adsorb CO2 and H2O, H2O and H2S.

I added 4A blue indicating molecular sieve. 4a blue indicating molecular sieve desiccant is a sodium alumina silicate molecular sieve injected with an inorganic metal salt moisture indicator. The desiccant is known to act as a molecular sieve with the bonus ability to tell visually when the molecular sieve achieves saturation. When active, the molecular sieve beads are blue. Then beads arrive at saturation, the color changes to beige demonstrating that the molecular sieve has reached equilibrium capacity and is then in need of regeneration.

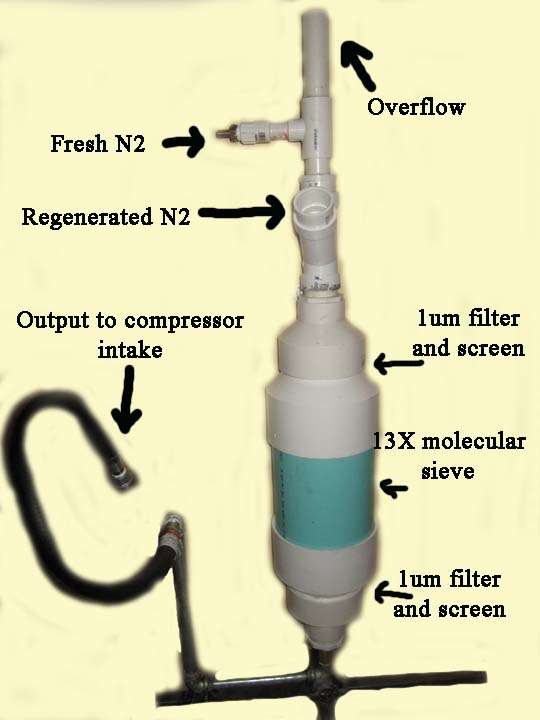

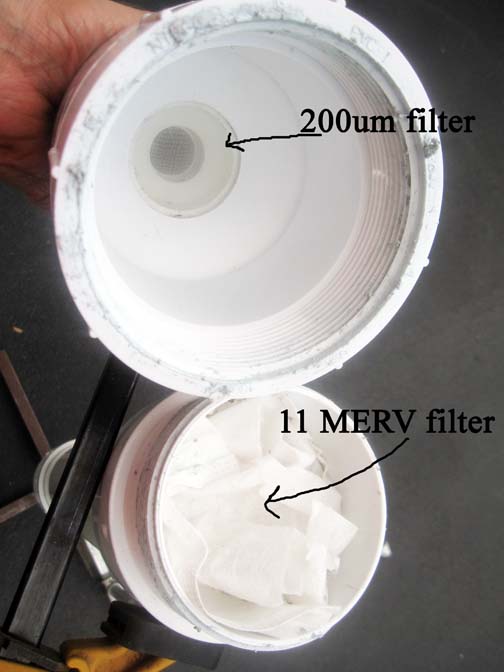

I constructed the canister out of PVC. The top and bottom had a mesh screen to support the weight of the material. I placed 11 MERV filter material on top and locked it with a ring to filter particles between 1 and 10um. Gas enters the top through the regeneration port. Fresh gas can enter through an additional port. Excess gas exits the top. This ensures that only the desired gas enters the system instead of room air, unless this is desired. After travelling through the material, the scubbed gas exists the bottom to the compressor intake port. A 10um filter and water trap serves as addition protection for the compressor.

Above one can see the 13X molecular sieve. One pound of a blue-indicating sieve is mixed with the 13X to serve as an indicator when the material is reaching exhaustion and needs regeneration. The material can absorb about 20% of its weight in water. Also shown is the filter material and ring to prevent particles from entering the stream.

Above are some of the air drying physical properties for 13x molecular sieve.

My new scrubber made from 4" PVC pipe and 4-to-2 inch reducers. The 200um mesh is glued between the reducer and a coupler. Also note that a threaded fitting is used to allow easy access into the system to remove the material for regeneration. Some plumber's sealant is used to ensure there are no leaks.

The 11 MERV filter material is 65% efficient at blocking 1-3um particles.